Dalian Sanhe Molding Co., Ltd.

The company's main business scope is mold design and manufacturing, mold parts and plastic products molding and manufacturing; stamping manufacturing and sales of metal parts; all molding equipment of the company are equipped with high-quality mold temperature regulators and corresponding auxiliary equipment, post-processing equipment, etc., complete supporting facilities, to provide sufficient guarantee for the quality of excellent products.

We are not the best, but we must be trying to do better.

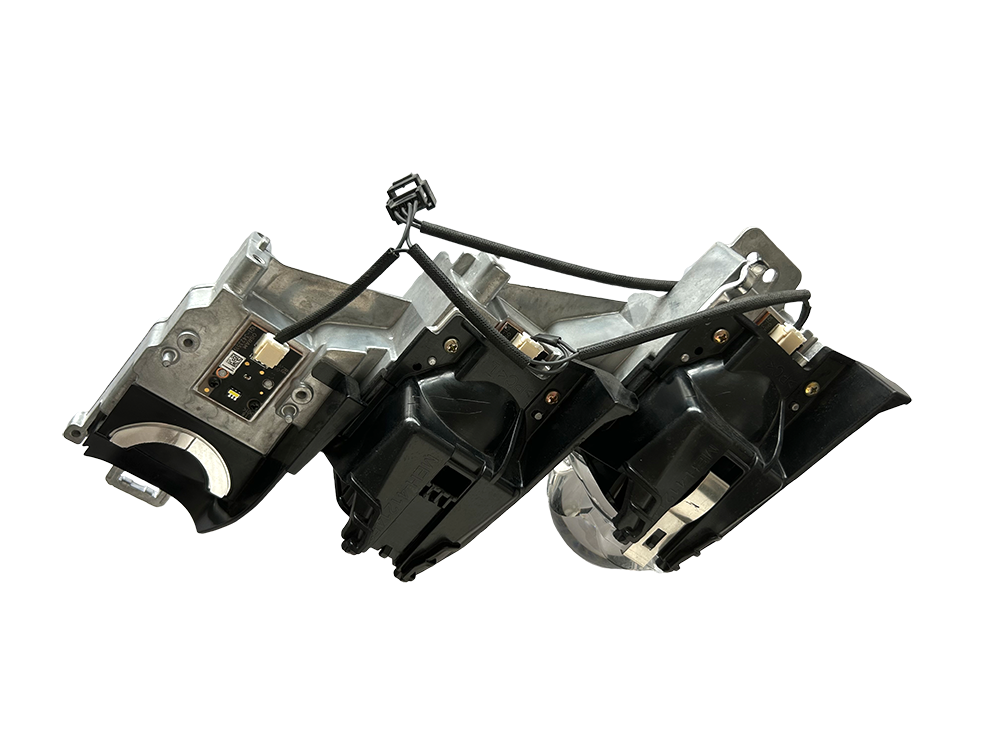

Injection molding

Here is the placeholder text

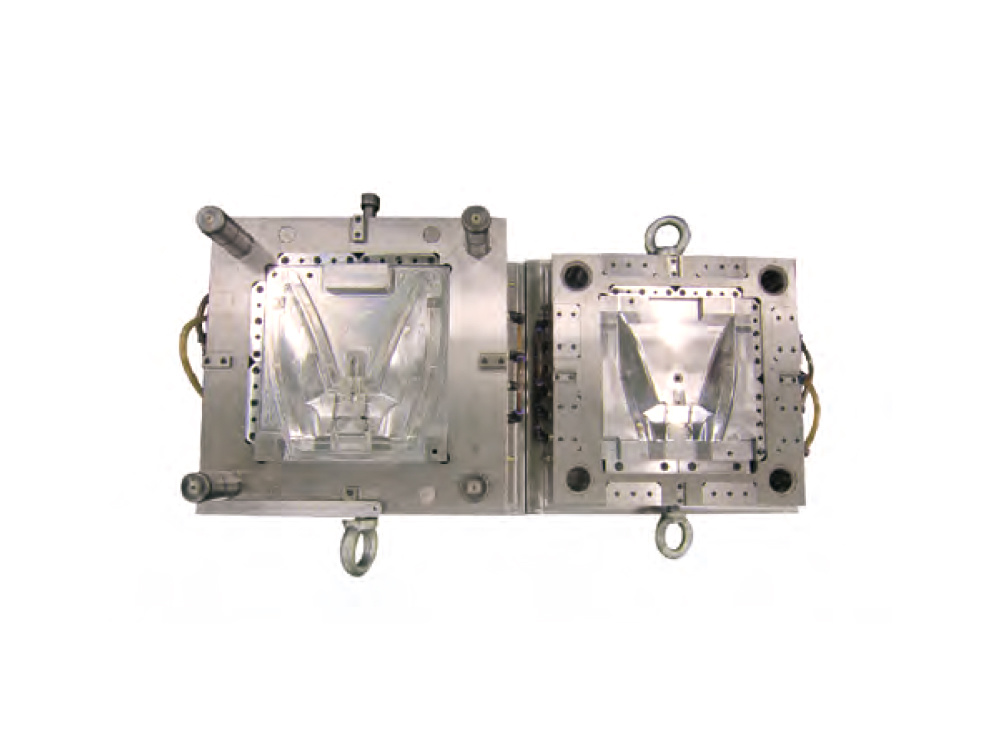

Injection molding

Injection molded structural components, functional components, and precision components for special purposes are widely used in fields such as transportation, postal and telecommunications, communication, construction, home appliances, computers, aerospace, and national defense.

View Details

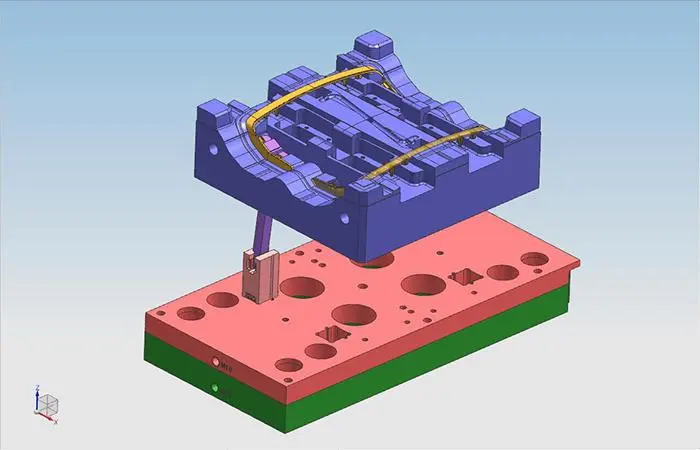

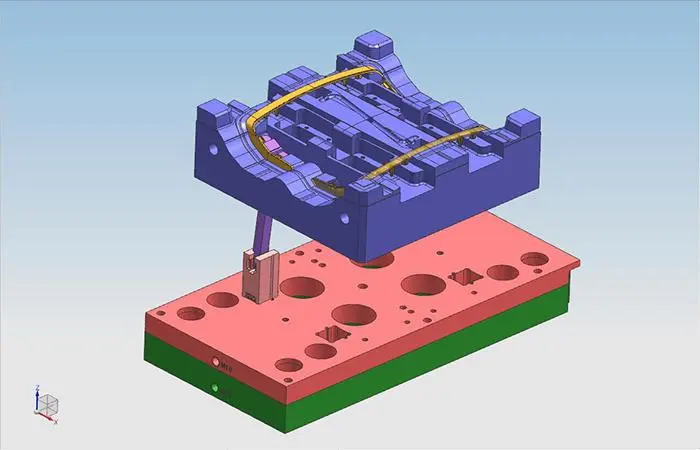

Mold design

Here is the placeholder text

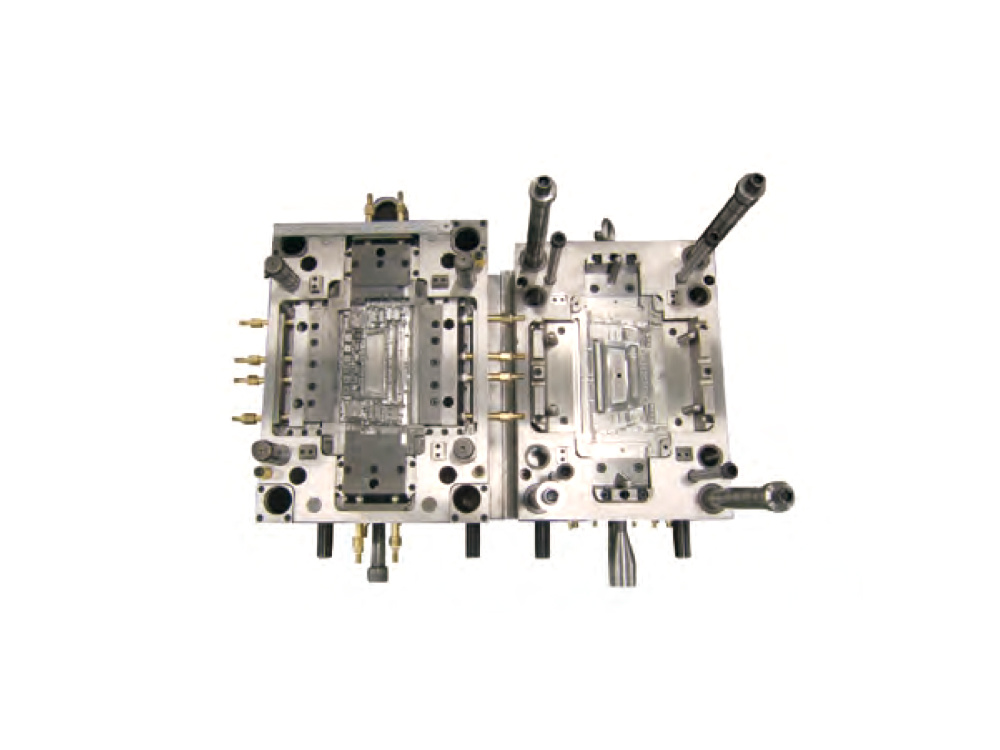

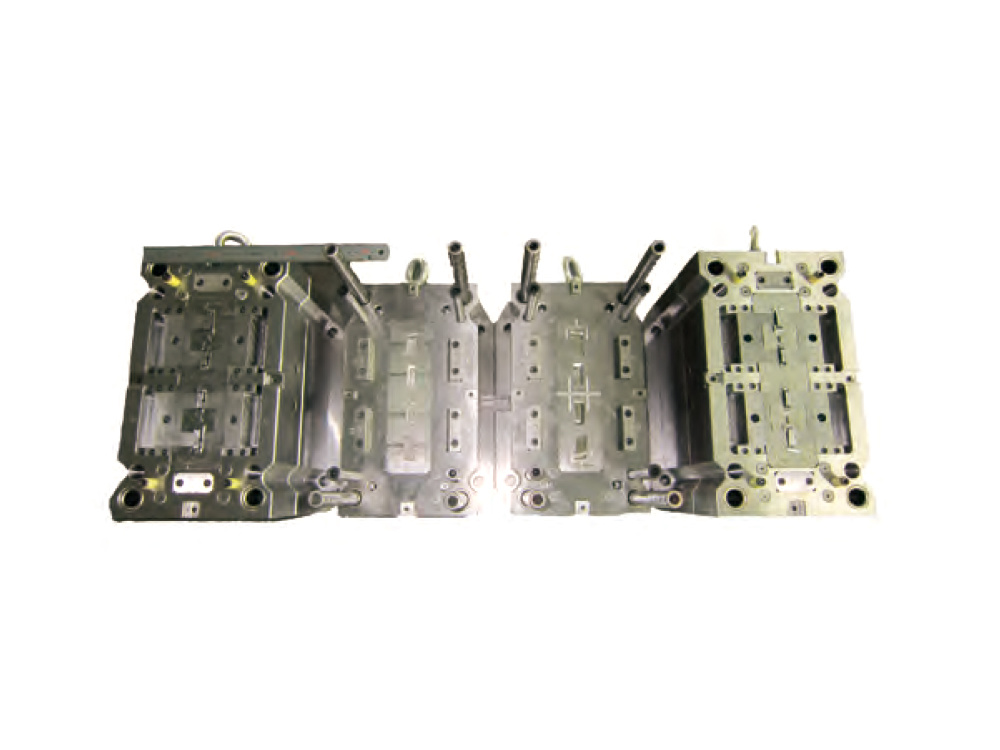

Mold design

Including cavity molds and cold stamping molds, based on traditional mold design, digital design tools are applied to improve the quality of mold design and shorten the mold design cycle.

View Details

Stamping forming

Here is the placeholder text

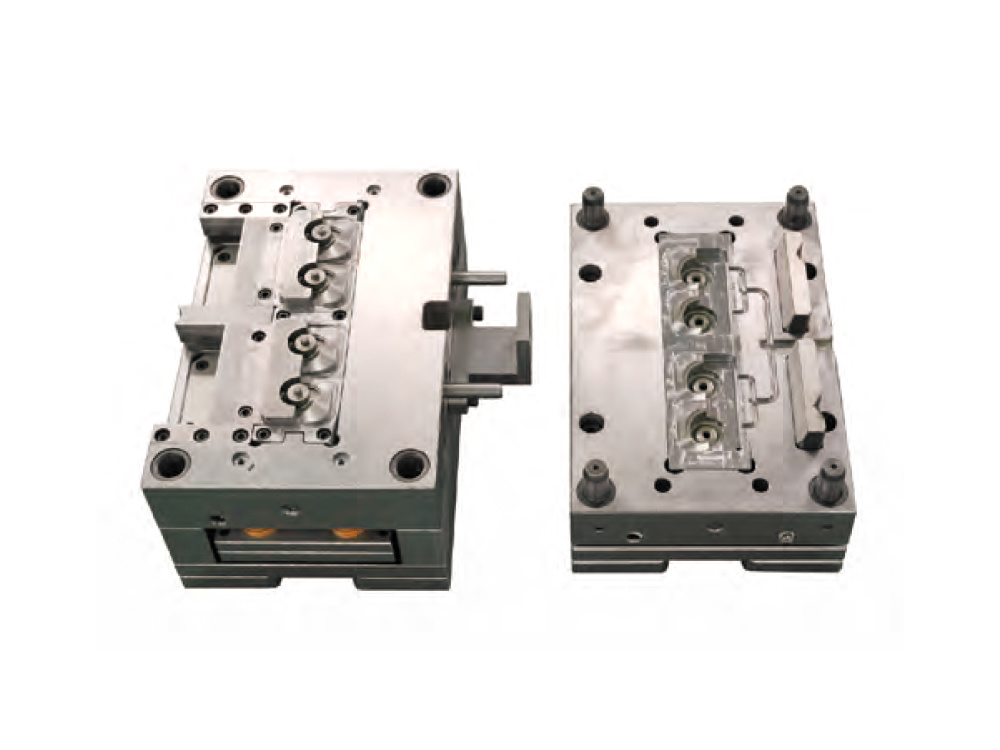

Stamping forming

By relying on a press and mold, external forces are applied to plates, strips, pipes, and profiles to cause plastic deformation or separation, thereby obtaining the required shape and size of the workpiece.

View Details

Plastic Products

Here is the placeholder text

Plastic Products

The molding process of synthetic resin or plastic generally includes the batching, molding, mechanical processing, bonding, modification, and assembly of plastic.

View Details

Metal Products

Here is the placeholder text

Metal Products

Including the manufacturing of structural metal products, metal tool manufacturing, container and metal packaging container manufacturing, stainless steel and similar daily metal products manufacturing, etc.

View Details

Products center

Storage environment

All molding equipment of the company are equipped with high-quality mold temperature regulators and corresponding auxiliary equipment, post-processing equipment, etc., complete supporting facilities, to provide adequate protection for the quality of excellent products. The company has specialized quality inspectors and inspection rooms. The inspection instruments include calipers, micrometers, altimeters, microscopes, projectors, etc.

Office Environment

All molding equipment of the company are equipped with high-quality mold temperature regulators and corresponding auxiliary equipment, post-processing equipment, etc., complete supporting facilities, to provide adequate protection for the quality of excellent products. The company has specialized quality inspectors and inspection rooms. The inspection instruments include calipers, micrometers, altimeters, microscopes, projectors, etc.

Production Environment

All molding equipment of the company are equipped with high-quality mold temperature regulators and corresponding auxiliary equipment, post-processing equipment, etc., complete supporting facilities, to provide adequate protection for the quality of excellent products. The company has specialized quality inspectors and inspection rooms. The inspection instruments include calipers, micrometers, altimeters, microscopes, projectors, etc.

NEWS

News

Pay attention to more three and dynamic, keep abreast of relevant information!

More information, oneHow does precision injection molding work?

Injection molding precision processing production requires 24 hours of continuous operation, generally in two shifts. There are many jobs in the injection molding workshop, the division of responsibilities is complicated, and the skill requirements for different positions are also different. In order to make the production operation of the injection molding workshop smoothly, it is necessary to manage the personnel, materials, equipment and tools involved in each link and each post, mainly including: raw material room, crushing room, batching room, production site, post-processing area, tool room, semi-finished product area, office and other regional operation and coordination management.

22

2023

/

09

Requirements for working conditions of injection molds

Plastic products have been widely used in industrial and agricultural production, transportation, communications, medical and health and people's daily life. The vast majority of these plastic products need to be produced by molds, so the performance requirements of plastic molds are getting higher and higher, the mold structure is becoming more complex, the manufacturing difficulty is greater, the production cycle is longer, and the manufacturing cost is higher. Shenzhen injection mold material selection is a very important part of the entire injection mold production process. The injection mold meets the work requirements of wear resistance, strength and toughness, the injection mold meets the process requirements, and the injection mold should meet the economic applicability.

22

2023

/

09

Mold injection molding why often gas discharge, what is the impact?

First of all, we need to understand where the generated steam sinks are mainly distributed. The vapor bubbles generated by the accumulation of air in the mold cavity are often distributed on the opposite part of the gate. The bubbles generated by the decomposition or chemical reaction in the plastic raw material are distributed along the thickness of the plastic part. The bubbles generated by the gasification of residual water in the plastic raw materials are irregularly distributed throughout the plastic parts. Gas is often generated in injection molds, which may be related to the following points

22

2023

/

09

Plastic mold production process, from material selection to the whole process of mold production

Plastic mold manufacturing material selection is very important, in general, the mold material can be divided into three categories, namely metal materials, wood and plastic. According to the requirements of the mold, choose the most suitable material to ensure the quality and performance of the mold.

28

2022

/

07

What are the commonly used cooling methods for plastic molds?

The role of the cooling system: 0: shorten the molding cycle and improve production efficiency; in the entire molding cycle, the cooling and curing time reaches 60% to 80%, so designing a reasonable cooling system is critical. 2: to improve product quality, not only to make the mold cooling, and try to make the mold to maintain a constant temperature, control the melt cooling speed, cooling speed is too fast will affect the filling, too slow will cause the product defects and molding cycle extension due to high temperature

10

2022

/

01

Contact Information

Add: No.98 -4-12, Tieshan East Road, Jinzhou District, Dalian

SAF Coolest v1.2 设置面板 UWFSX-ZSUH-MQAZE-ZXQ

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page

中文版

中文版 English

English 日本語

日本語